RAF Odiham Station Workshops have been heavily involved in the recent Service Modification work to produce a solution to the ongoing problem of Articles Falling Off Aircraft (AFOA) relating to the Aft MRH Droop Stop Shrouds on Boeing CH47 Chinook Helicopters.

The Boeing CH47 Chinook aircraft is fitted with droop stops on the Aft main rotor head to prevent the blades from contacting the aircraft as the aircraft shuts down. To protect the droop stops from ice accretion that may lead to the stops not engaging, droop stop shroud assemblies manufactured from fibreglass consisting of a main body complete with inspection cover and a lower shield are fitted around the stops. Several reports had identified that inspection covers and/or shields had detached in flight leading to Articles Falling Off Aircraft (AFOA) events. Direction was given to urgently develop a modification to reduce/eliminate the risk of the covers and shield detaching – and RAF Odiham Station Workshops were placed at the forefront of the modification alongside Subject Matter Experts (SME) located on Station to provide expert engineering advice and guidance.

.jpg)

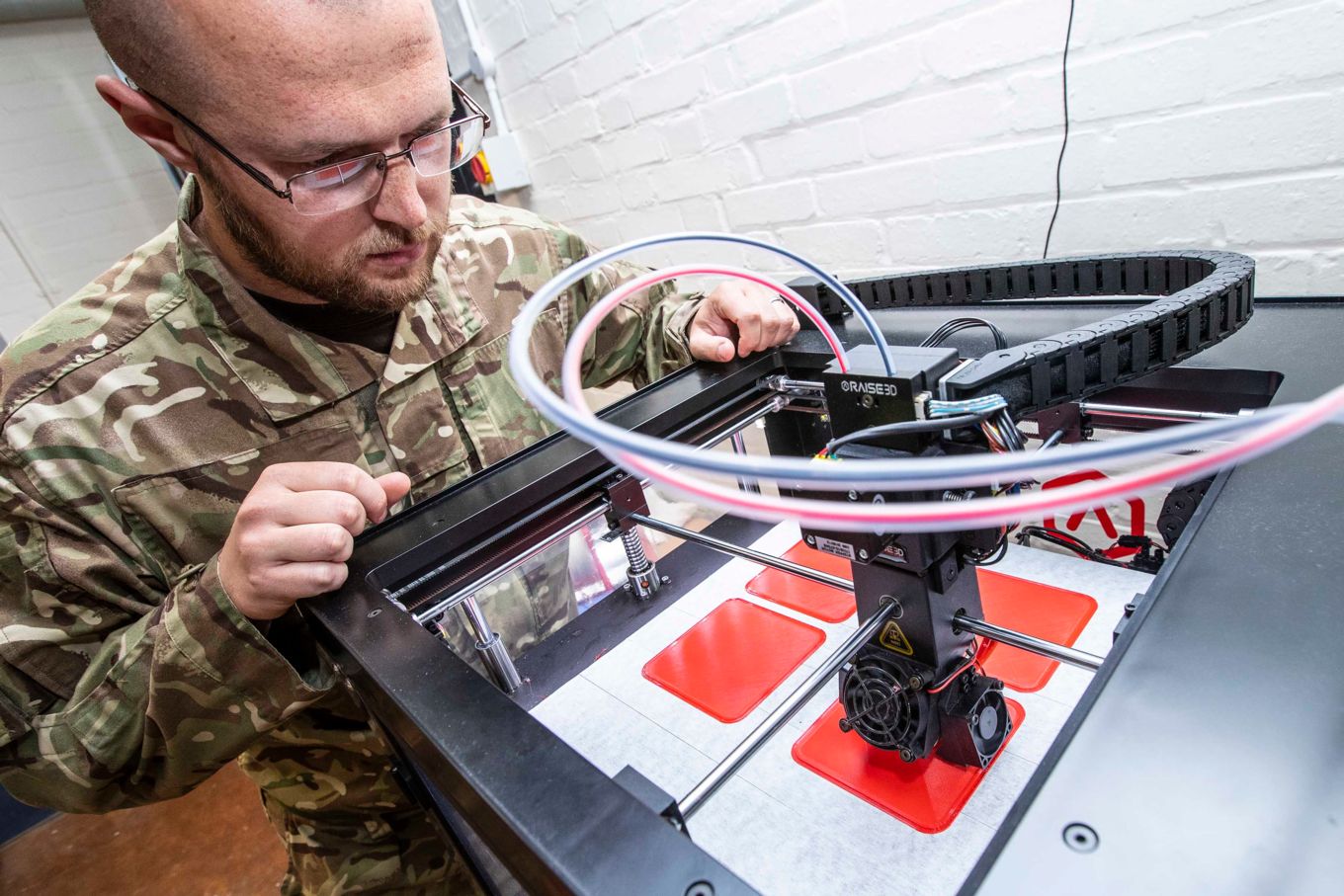

As an SME in the use of 3-D printing, Cpl Boyle from RAF Odiham Station Workshops took initial design concepts produced by the engineering SMEs then drew extensively on his experience gained whilst on ASTRA placement with STARCHASER Industries (UK space rocket design/manufacturing company) to manipulate these designs allowing production of 3-D printed prototypes of the parts and tooling required in a manner such that they could be rapidly manufactured. Throughout this activity, Cpl Boyle mentored SAC’s Hunt, Becket and Osler from Station Workshops in the 3-D printing and design techniques resulting in the Team producing an excellent set of prototypes that provided the confidence in progressing the required modification.

Full scale production of modification parts is now running at ‘full steam’ at RAF Odiham to ensure all Chinooks remain protected from the elements as the colder weather approaches and that when fitted, the risk of AFOA is effectively eliminated.

The extensive use of 3-D printing has again demonstrated its huge benefit and potential at RAF Odiham – and the support of ASTRA together with the opportunity to undertake placements such as that given by STARCHASER Industries significantly enhances the knowledge and experience necessary to use Additive Manufacturing to its fullest capability.