Over a million pounds will be saved in RAF Typhoon repairs thanks to a new process introduced by Wittering’s No 71 Inspection & Repair (IR) Squadron.

Most military aircraft are designed to be towed by their nosewheel legs. Over time, the wear and tear caused by towing can accumulate and create damage that goes deeper than the surface. Until now, damaged nosewheel legs were removed from the aircraft and sent away for repair, costing around £20K every time.

Image By: Supplied Image

Based at RAF Wittering in Cambridgeshire, 71 (IR) Sqn’s principal role is to repair damaged structure on UK fixed-wing military aircraft in deployed locations. The Squadron has its own designers, who devise repair solutions in circumstances where conventional fixes may not be effective or available. 71 (IR) Sqn’s aircraft mechanical technicians are skilled in precision metalwork and the use of composite materials like carbon fibre.

The Typhoon is the backbone of the RAF’s combat capability. It is an extremely agile, multi-role, combat aircraft which is used in all the RAF’s current operations.

The new process allows the Typhoon nosewheel legs to be repaired whilst still fitted to the aircraft, saving both time and money, and decreasing the amount of time the Typhoon is grounded. Structurally sound landing gear is vital to an aircraft. When not flying the weight of an aircraft sits entirely on its landing gear, and the legs have to withstand the stresses of landing and being towed.

.jpg)

Image By: Supplied Image

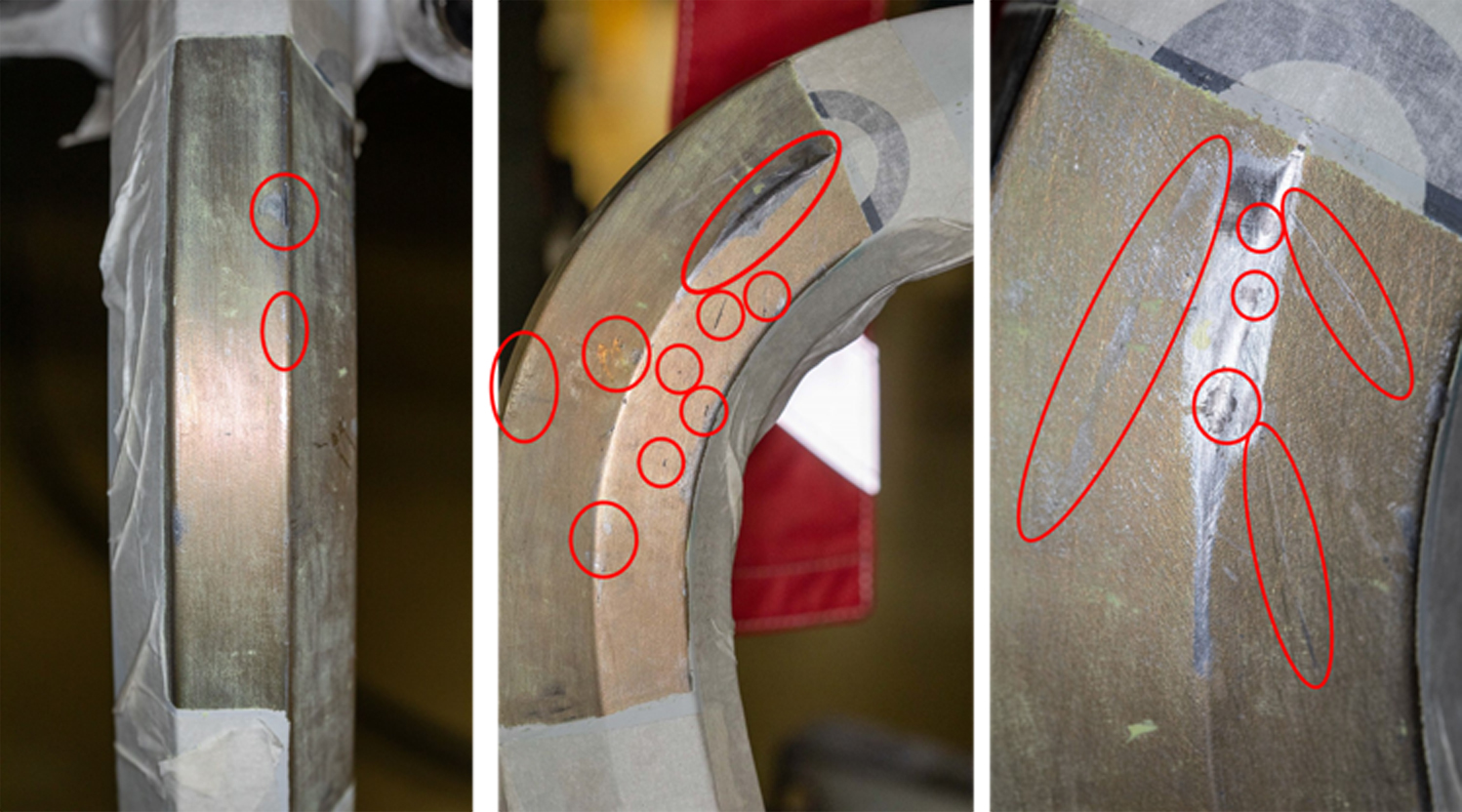

Squadron Leader Allen Auchterlonie is an RAF Engineer and the Officer Commanding of 71 (IR) Squadron. He said: “We can assess the damage to the nosewheel leg and remove the damaged material, a layer at a time, until we can see the undamaged structure underneath the surface. Then it’s a matter of building the surface up again, a layer at a time, so that the finished leg is structurally sound, protected against corrosion and ready to be primed and painted.”

Recognising the capabilities of their own talented team, 71 (IR) Squadron approached Project ASTRA for the £35K needed purchase the new equipment and training. Project ASTRA’s aim is to build an air force fit for the next generation by embracing innovative technologies, new ideas, and by involving ideas and contributions from the whole workforce.

Image By: Supplied Image

Squadron Leader Auchterlonie said: “Using this new capability, the first two repairs have been completely successful and have significantly extended the lives of both nosewheel legs. We intend to increase the number of repaired nosewheel legs in the very near future. Multiply this across the Typhoon fleet and it will amount to around £1.2 million in savings against a £35K investment. Our next project is to see how we can apply this process to other aircraft types in the RAF.”

71 (IR) Sqn is part of the RAF Support Force, which has its headquarters at RAF Wittering. The Support Force brings together most of the capabilities and skills needed to sustain modern air operations and exercises; specialist engineering and logistics, advanced military communications, tactical medical services, mountain rescue and music services.

Image By: Supplied Image

Sergeant Matthew Walker is one of 71 (IR) Sqn’s most experienced engineers and worked on the first repairs. He said: “With our target to do our first 2 in 5 days we had managed to do the 2 aircraft over a 2 day period. It was a huge success and I was really proud of the team. When we finished and cleaned the work area up, it was like we were looking at a brand new leg. A great sense of achievement and a huge motivator for future taskings.”

Group Captain Nick Huntley is Deputy Commander of the RAF Support Force. He said: “I am deeply impressed by the way 71(IR) Squadron continue to seek innovative methods and technologies to enhance their repair capabilities and provide further in-house specialist services. Sqn Ldr Auchterlonie and his team have worked collaboratively with Project ASTRA and the benefits are clear to see, not just in cost saving but in ensuring RAF capabilities are readily available to Defence.”