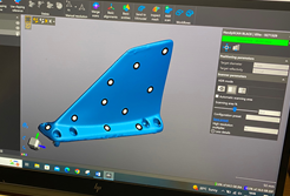

Project ADDITIVE HANDYSCAN is supporting specialist engineering tasks.

The Project, led by 71 (Inspection & Repair) Squadron at RAF Wittering involves the use of a hand-held 3D scanner, which can capture accurate three-dimensional data of aircraft parts. The data can then be used for highly-skilled engineering tasks such as assessing structural damage, creating components that are not available by standard supply routes, or enabling the Squadron to conduct non-destructive testing.

It has already been used in several situations. For example, the Poseidon MRA1 required a mount for an Underwater Locator Beacon. The mount had to be designed from scratch but to do that the teams needed precise measurements of the item and where it would be fitted on the aircraft. The 3D scanner was put to use.

Normally it can take several visits throughout the design process to make sure the product is exactly what is required. The accurate measurements given by the 3D scanner were so useful that there was only one visit needed at the start of the design process and the perfect product was quickly delivered.

It's not just the Poseidon that has benefited from Project ADDITIVE HANDYSCAN though. It can quickly produce accurate data time and time again, so it has also been used during the initial design phases of things such as supplementary aerial baseplate covers for the Typhoon. The speed and accuracy of the scanner also means that it is well suited to tasks such as mapping dents on the surfaces of Advanced Medium Range Air-to-Air Missiles that helps identify potential corrosion damage.